Why Upgrade to Aluminum Parts for Your Tevo Tarantula

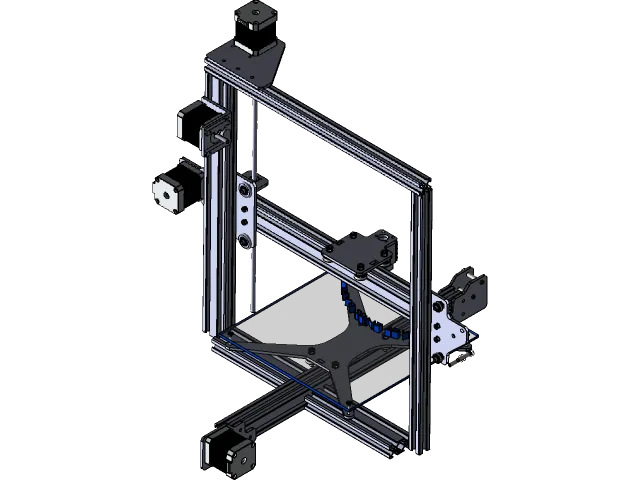

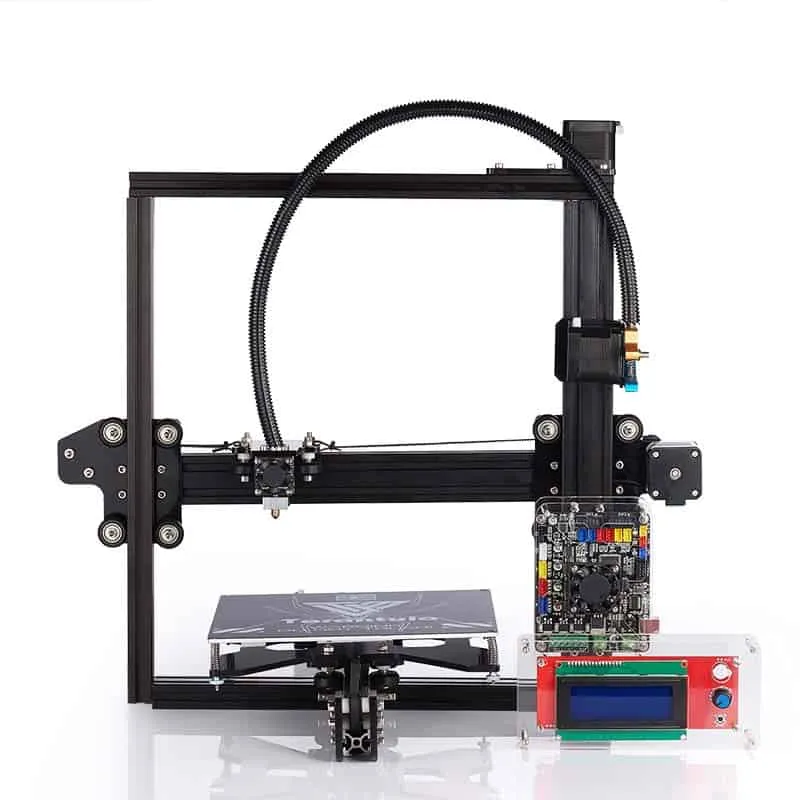

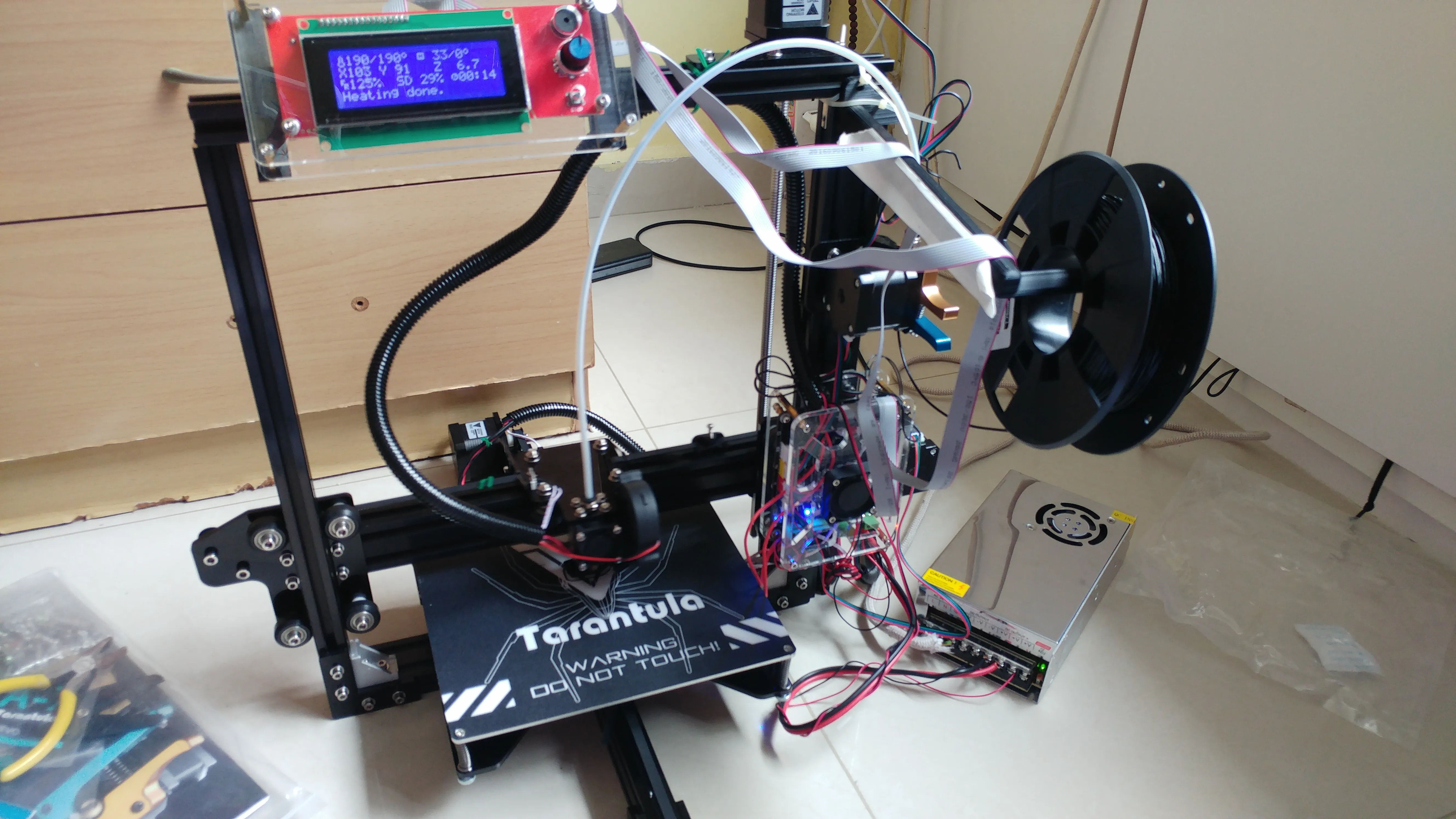

The Tevo Tarantula, a popular choice for 3D printing enthusiasts, offers a great entry point into the world of additive manufacturing. However, like any machine, it can be improved. One of the most effective ways to enhance your printing experience and the longevity of your Tevo Tarantula is to upgrade its plastic components with high-quality aluminum parts. Aluminum parts provide significant advantages over their plastic counterparts, leading to more reliable and higher-quality prints. This guide explores the benefits of upgrading to aluminum parts and highlights seven key upgrades that can transform your Tevo Tarantula.

Enhanced Durability

One of the primary benefits of aluminum parts is their superior durability. Unlike plastic, aluminum is resistant to warping, cracking, and breaking under the stress and heat generated during 3D printing. This is especially crucial for components that experience significant wear and tear, such as the extruder lever or bed leveling knobs. Replacing these parts with aluminum equivalents ensures that your printer can withstand extended use and maintain its structural integrity, resulting in fewer maintenance issues and more consistent prints. This enhanced durability translates to a longer lifespan for your 3D printer and reduces the need for frequent replacements.

Reducing Wear and Tear

Plastic parts are prone to wear and tear due to friction, heat, and the constant movement of the printer’s components. Aluminum parts, being much more robust, significantly reduce this wear and tear. This is particularly noticeable in areas like the X and Y-axis carriages, where the constant back-and-forth motion can quickly degrade plastic components. By upgrading to aluminum, you minimize the risk of parts becoming loose, misaligned, or failing altogether. This reduction in wear and tear ensures that your printer operates smoothly and accurately, leading to higher-quality prints and less downtime for maintenance.

Improved Print Quality

The enhanced stability and precision offered by aluminum parts directly contribute to improved print quality. Aluminum components are less susceptible to flexing and deformation, ensuring that your printer maintains accurate dimensions and precise movements during the printing process. This is especially beneficial for intricate designs and complex geometries. The reduced vibrations and improved stability provided by aluminum upgrades result in smoother surfaces, sharper details, and overall better print quality. Investing in aluminum parts is a worthwhile endeavor for anyone looking to achieve professional-looking results with their Tevo Tarantula.

Top 7 Aluminum Part Upgrades for Your Tevo Tarantula

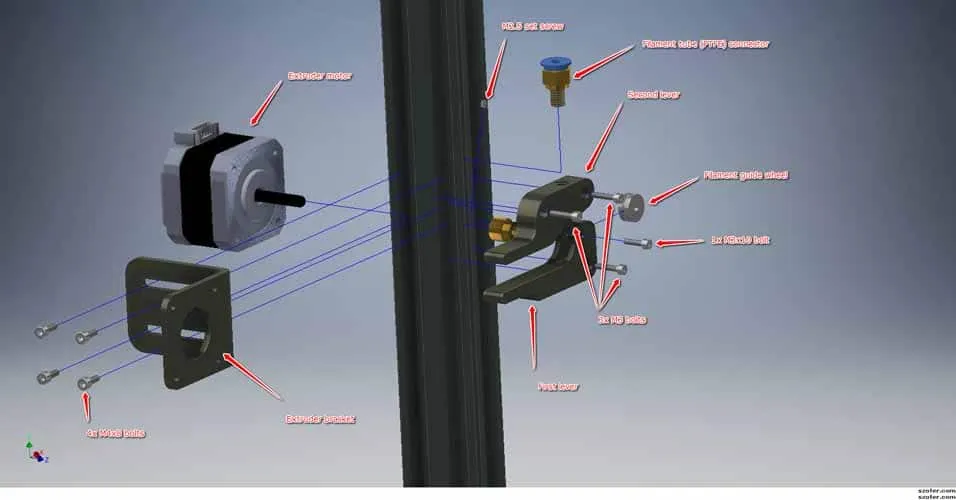

Aluminum Extruder Lever Upgrade

The extruder lever is a crucial component for feeding filament into the hotend. The original plastic lever can be prone to cracking or breaking, especially with repeated use or the application of excessive force. An aluminum extruder lever offers superior durability and a more reliable filament feeding mechanism. This upgrade is relatively inexpensive and straightforward to install, making it an excellent starting point for improving your printer’s performance and reducing the likelihood of filament feeding issues. This upgrade greatly reduces filament jamming.

Benefits of an Aluminum Extruder Lever

- Increased durability and lifespan

- More consistent filament feeding

- Reduced risk of breakage

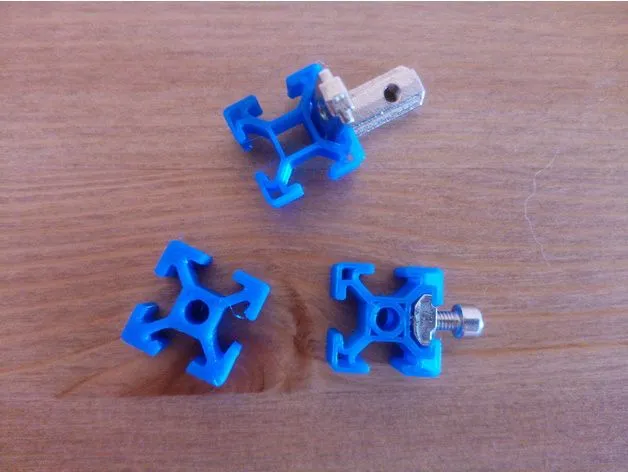

Aluminum Bed Leveling Knobs Upgrade

Bed leveling is a critical aspect of 3D printing, and the knobs used to adjust the bed often wear down or become loose over time. Upgrading to aluminum bed leveling knobs provides a more stable and precise leveling mechanism. These knobs are typically designed with improved grip and durability, making it easier to fine-tune the bed height and maintain a level printing surface. This upgrade is simple to install and offers significant improvements in print adhesion and first-layer quality.

Advantages of Aluminum Bed Leveling Knobs

- Improved bed leveling stability

- Enhanced grip for easier adjustment

- Increased durability and longevity

Aluminum Z-Axis Motor Mounts Upgrade

The Z-axis motor mounts are essential for the vertical movement of the print bed. The stock plastic mounts can flex or vibrate, leading to inconsistent layer heights and print quality issues. Aluminum Z-axis motor mounts provide a more rigid and stable platform for the motor, minimizing vibrations and ensuring precise vertical movement. This upgrade contributes to improved print accuracy and reduces the likelihood of layer shifting or other Z-axis-related defects.

Why Upgrade to Aluminum Z-Axis Motor Mounts

- Enhanced stability and reduced vibrations

- Improved print accuracy and layer consistency

- More reliable vertical movement

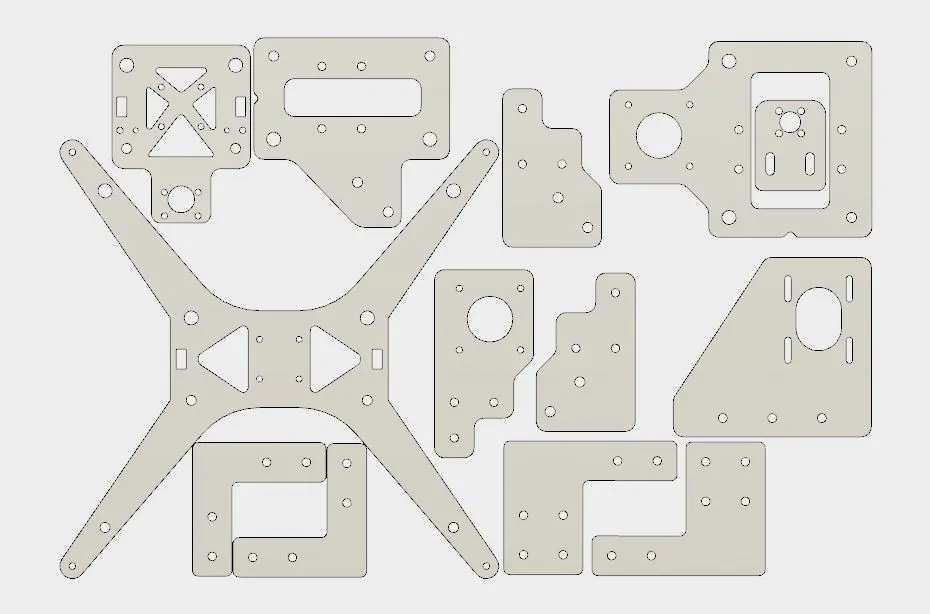

Aluminum X-Axis Carriage Upgrade

The X-axis carriage holds the hotend and moves it horizontally. An aluminum X-axis carriage offers increased rigidity, reducing flex and vibration during printing. This leads to more precise movements and improved print quality, especially at higher speeds. This upgrade is particularly beneficial for users who print complex models or require high levels of detail.

Advantages of Aluminum X-Axis Carriage

- Increased rigidity and stability

- Reduced flex and vibration

- Improved print quality and accuracy

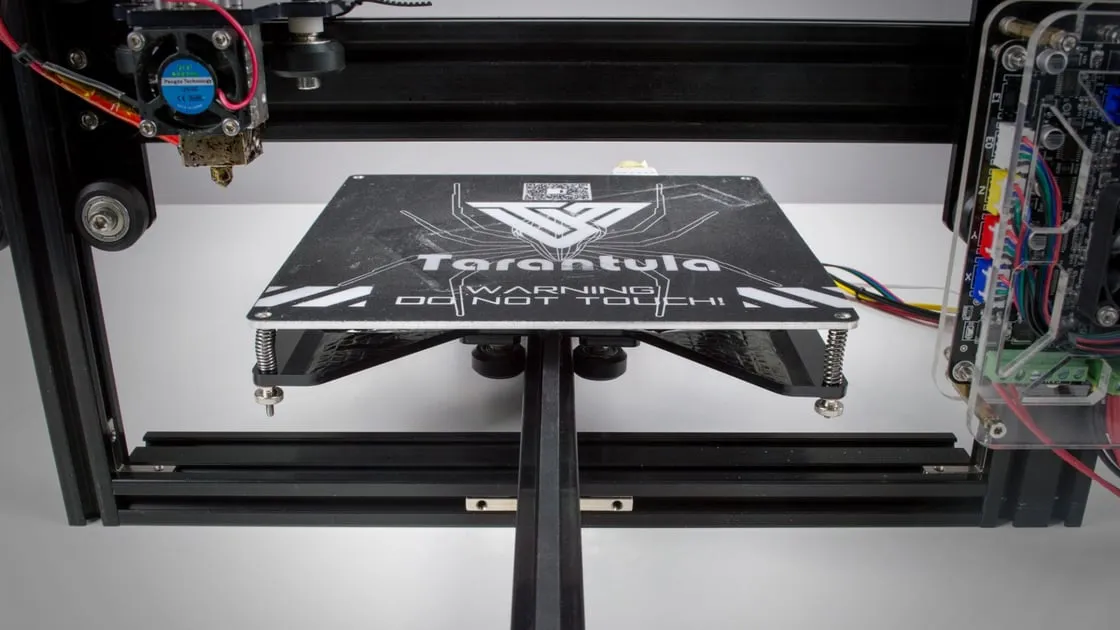

Aluminum Y-Axis Carriage Upgrade

The Y-axis carriage supports the print bed and moves it back and forth. An aluminum Y-axis carriage provides increased stability and reduces the potential for warping or flexing, which can affect the first layer adhesion and overall print quality. This upgrade is especially useful for larger prints, where the bed’s weight and inertia can impact print accuracy.

Benefits of Aluminum Y-Axis Carriage

- Enhanced bed stability

- Reduced flex and warping

- Improved first-layer adhesion and print quality

Aluminum Hotend Upgrade

Upgrading the hotend with aluminum components can improve heat dissipation and overall performance. An aluminum hotend is often more durable than the stock components and can withstand higher temperatures, allowing for the use of a wider range of filaments. This upgrade can also contribute to more consistent temperature control, which is crucial for achieving high-quality prints.

Advantages of Upgrading to an Aluminum Hotend

- Improved heat dissipation

- Increased durability

- Wider range of filament compatibility

- More consistent temperature control

Aluminum Belt Tensioners Upgrade

Belt tensioners are critical for ensuring that the belts on your 3D printer are properly tensioned. Aluminum belt tensioners provide a more precise and durable way to adjust belt tension compared to the stock plastic components. Maintaining proper belt tension is essential for print accuracy, as loose belts can lead to layer shifting and other print defects. The aluminum upgrades often come with improved adjustment mechanisms and are less likely to wear out or fail.

Why Use Aluminum Belt Tensioners

- Precise belt tension adjustment

- Increased durability and lifespan

- Improved print accuracy

Choosing the Right Aluminum Parts

When selecting aluminum parts for your Tevo Tarantula, consider a few important factors to ensure that you are making the right choices for your needs and budget. Quality, compatibility, and budget are all crucial considerations in your upgrade process.

Material Quality

The quality of the aluminum used in the parts is a crucial factor. Look for parts made from high-grade aluminum alloys, as they offer the best balance of strength, durability, and resistance to corrosion. Check the product specifications to ensure that the parts are made from a suitable aluminum alloy like 6061 or similar, often used in the 3D printing space. Also, consider the finish of the parts. Anodized aluminum parts are often preferred because they offer increased surface hardness and resistance to wear.

Compatibility

Ensure that the aluminum parts you choose are compatible with your specific Tevo Tarantula model. Some upgrades may only fit certain versions of the printer. Carefully review the product descriptions and check for any compatibility notes. Look for reviews from other Tevo Tarantula owners to ensure that the parts fit properly and function as expected. Verify the dimensions and mounting points to avoid any issues during installation.

Budget Considerations

Aluminum parts can vary in price. It is a good idea to set a budget before you start shopping. While investing in high-quality aluminum parts is generally recommended, you don’t need to upgrade everything at once. Prioritize the upgrades that offer the most significant improvements in print quality and reliability. Start with the essential upgrades, such as the extruder lever or bed leveling knobs, and then consider other parts as your budget allows.

Installation and Maintenance

Installing aluminum parts on your Tevo Tarantula is typically straightforward, but it’s essential to follow the manufacturer’s instructions carefully. Here’s some general guidance and tips for maintaining your upgrades.

Step-by-Step Installation Guide

Before you begin, make sure that your 3D printer is turned off and unplugged from the power source. The process can vary depending on the specific part and manufacturer. Some parts may require you to disassemble existing components. Use appropriate tools, such as Allen wrenches and screwdrivers, to remove the old plastic parts and install the new aluminum upgrades. Carefully align the new parts and secure them, ensuring that all screws and bolts are tightened properly. Avoid over-tightening, which can damage the parts. Refer to online tutorials or videos for visual guidance. After installing, check the printer’s operation by manually moving the print bed and the extruder to ensure they move freely and do not bind.

Regular Maintenance Tips

While aluminum parts are more durable than plastic, they still require some maintenance. Regularly inspect the aluminum parts for any signs of wear, such as loose screws or bolts. Clean the parts periodically to remove any dust or debris that might accumulate. If you notice any issues, such as binding or misalignment, address them promptly. Keeping your 3D printer clean and well-maintained will ensure optimal performance and longevity. Also, ensure that you are using the correct lubricants for the printer’s moving parts.

Conclusion

Upgrading your Tevo Tarantula with aluminum parts is a wise investment for any 3D printing enthusiast. The enhanced durability, reduced wear and tear, and improved print quality offered by aluminum components can significantly enhance your printing experience. By focusing on the top seven aluminum part upgrades discussed in this guide, you can transform your Tevo Tarantula into a more reliable, accurate, and enjoyable 3D printer. Remember to choose high-quality, compatible parts and follow installation and maintenance guidelines for the best results. With these upgrades, you can unlock the full potential of your Tevo Tarantula and achieve professional-quality prints.