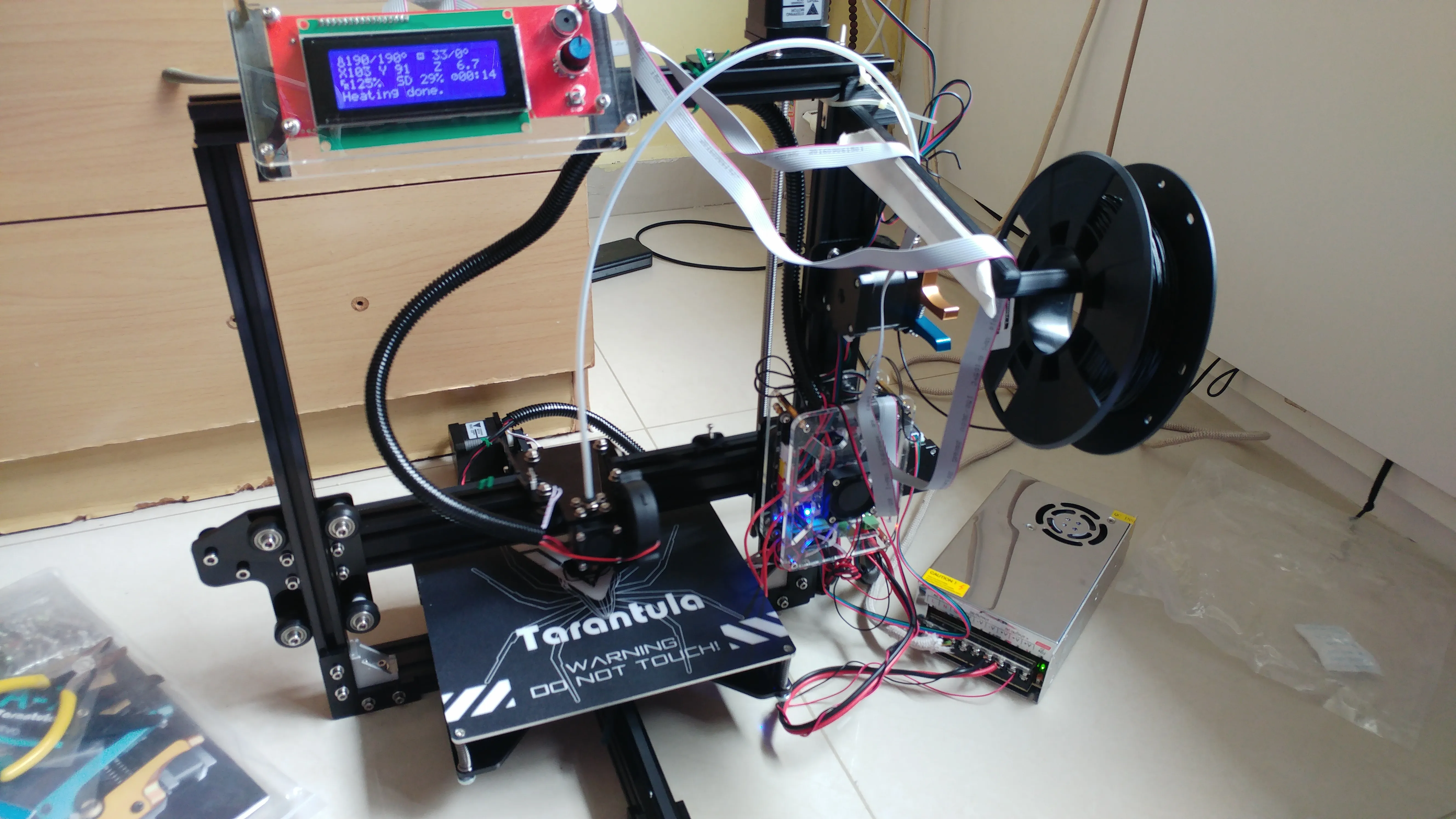

What are Aluminum Parts?

In the realm of 3D printing, especially with the Tevo Tarantula, upgrading to aluminum parts represents a significant leap in performance and longevity. Unlike the stock components often made of plastic or other less robust materials, aluminum parts offer superior strength, stability, and thermal conductivity. This shift to aluminum is a cornerstone in enhancing your 3D printing experience, allowing for more precise prints, faster printing speeds, and overall improved reliability of your 3D printer. Aluminum, being a lightweight yet incredibly durable metal, is an ideal choice for various components within the Tevo Tarantula, from structural elements to critical moving parts. Understanding the advantages of this upgrade is the first step in transforming your printer into a more efficient and reliable machine. This is a perfect starting point before delving into how each specific aluminum part can enhance your Tevo Tarantula.

Benefits of Aluminum Parts for Your Tevo Tarantula

The advantages of integrating aluminum parts into your Tevo Tarantula are multifold, touching on aspects of durability, performance, and print quality. Replacing key components with aluminum can significantly enhance the overall capabilities of your 3D printer. The following sections detail how each benefit directly contributes to a more satisfying and efficient 3D printing process. From the strength of the new components to the precision of your prints, upgrading to aluminum parts provides a solid foundation for any 3D printing project.

Increased Durability

One of the most immediate benefits of using aluminum parts is the marked increase in durability. Aluminum’s inherent strength allows it to withstand the stresses and strains that plastic parts, especially those in the Tevo Tarantula, may succumb to over time. This added durability ensures that your printer can handle more demanding projects, operate at higher speeds, and endure a longer lifespan overall. For example, an aluminum frame reinforcement provides a much more stable base compared to the original plastic frame, reducing vibrations and flex during printing, leading to more consistent results. Replacing fragile plastic components with aluminum directly contributes to the long-term reliability of your 3D printer.

Improved Performance

Beyond durability, aluminum parts significantly improve the performance of your Tevo Tarantula. Aluminum’s superior thermal conductivity allows for better heat management, which is crucial for consistent print quality. For instance, an aluminum hotend will distribute heat more evenly, reducing the chances of nozzle clogs and ensuring smoother filament flow. Additionally, the precision and stability of aluminum parts contribute to more accurate movements and finer details in your prints. Upgrading components like the extruder or the Z-axis stabilizer with aluminum versions directly enhances the accuracy and speed at which your printer operates, pushing the boundaries of what the Tevo Tarantula is capable of. This also leads to more consistent and reliable print results.

Enhanced Print Quality

The combination of increased durability and improved performance culminates in enhanced print quality. Aluminum parts reduce vibrations, provide a more stable platform, and allow for more precise control over the printing process. This means fewer layer shifts, reduced warping, and the ability to print complex designs with greater fidelity. Furthermore, the improved thermal management offered by aluminum components, such as the hotend, contributes to better filament melting and extrusion, resulting in smoother surfaces and finer details. Ultimately, upgrading to aluminum parts gives you the ability to produce professional-quality prints consistently. The upgrade gives the printer better mechanical stability for better results.

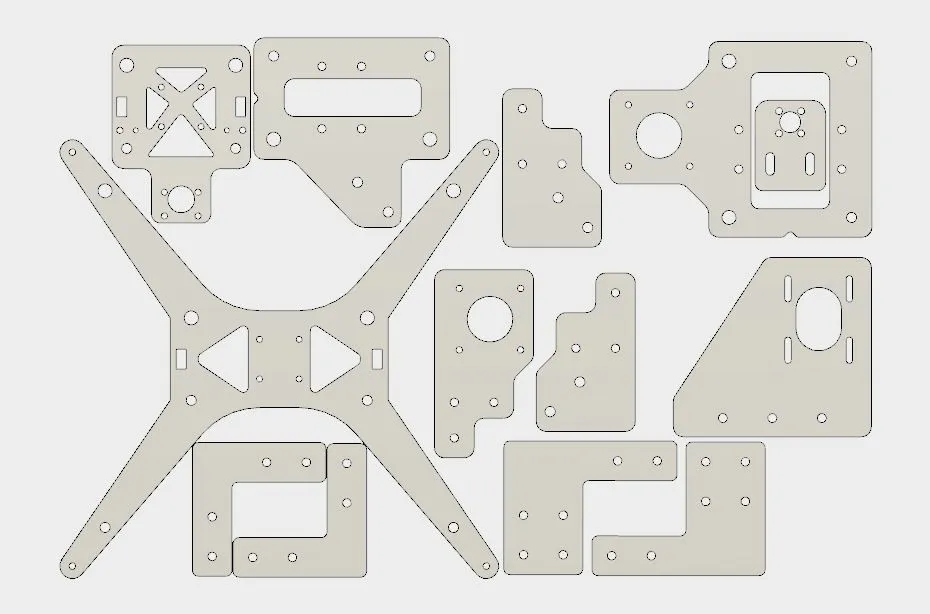

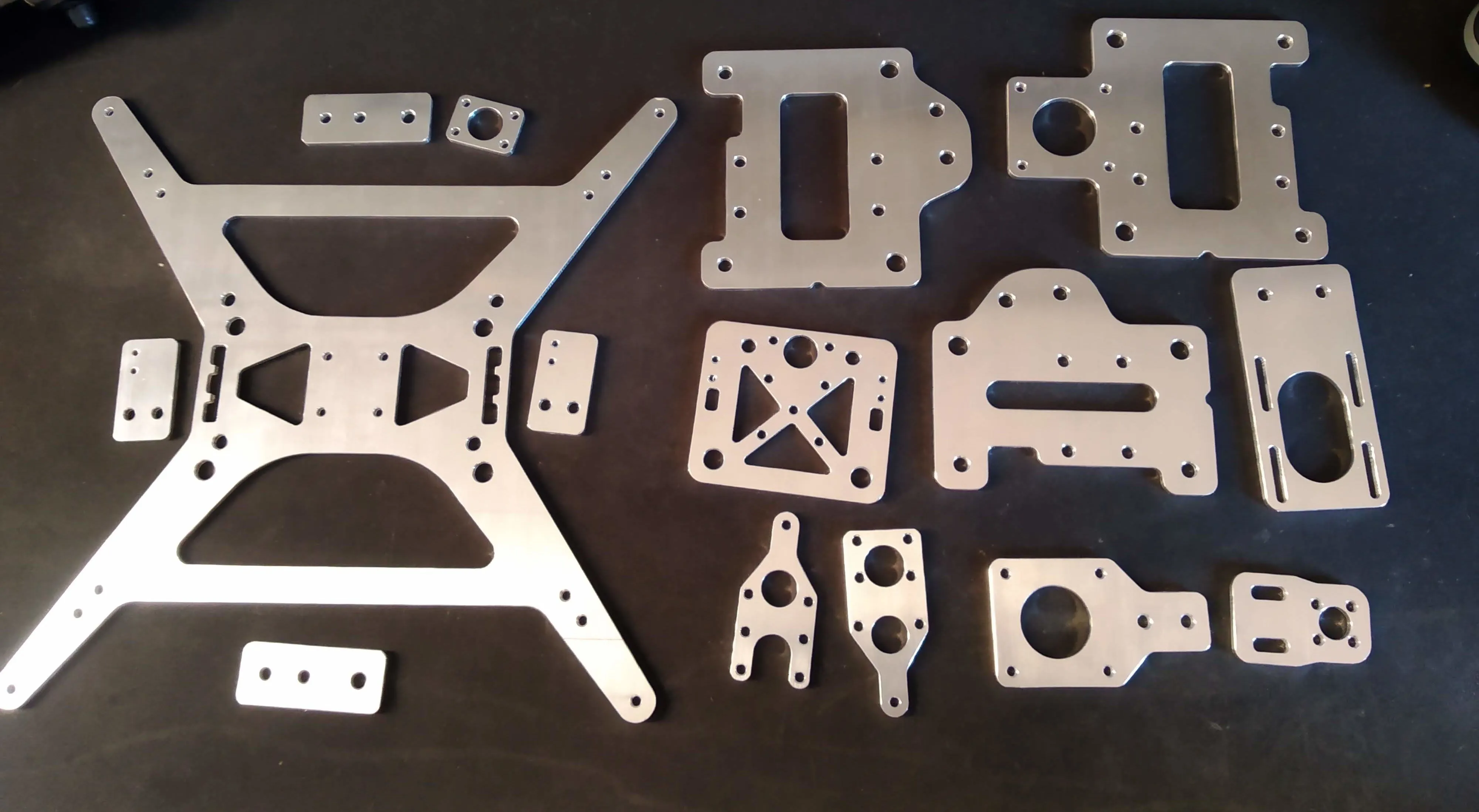

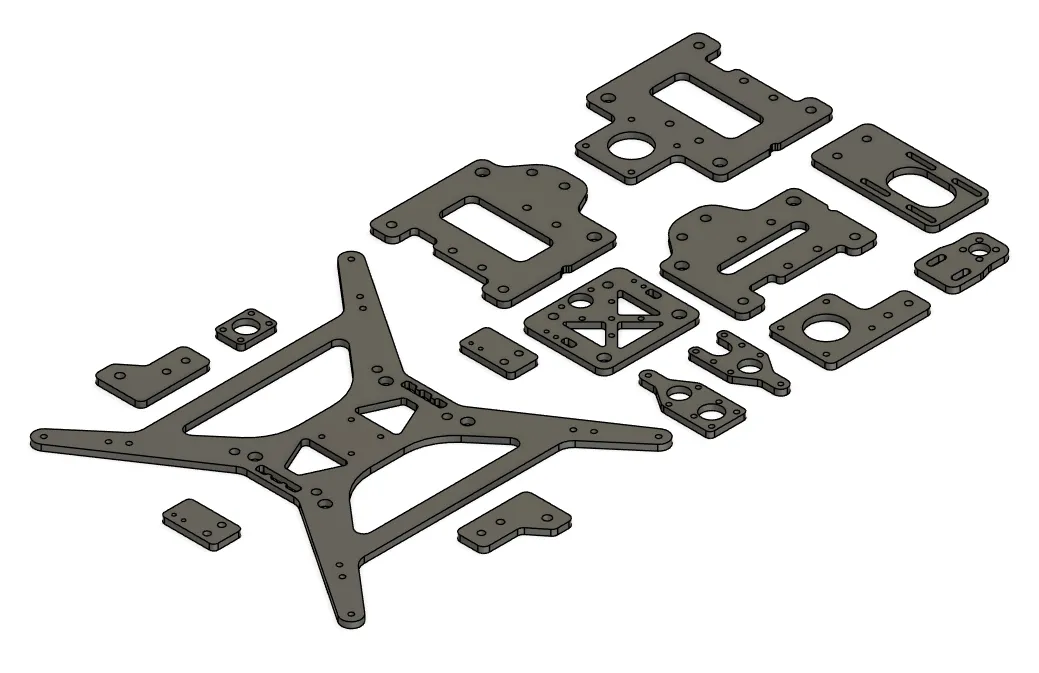

Top 5 Aluminum Upgrades for Tevo Tarantula

Selecting the right aluminum upgrades can greatly enhance your Tevo Tarantula’s capabilities. Here’s a look at five essential aluminum parts that will transform your 3D printing experience. Each of these upgrades offers specific benefits, from improving structural integrity to enhancing thermal management, collectively contributing to a more reliable and high-performing printer. Consider these parts as key components for maximizing the potential of your Tevo Tarantula, leading to better print quality and overall user satisfaction.

Aluminum Extruder

Replacing the plastic extruder with an aluminum version is a foundational upgrade. An aluminum extruder provides increased grip on the filament, reducing slippage and ensuring a consistent flow of material. This results in more accurate extrusion, leading to better print quality, especially with flexible filaments. Aluminum extruders are typically more durable and less prone to cracking or wear, improving the overall reliability of the filament feeding system. This is a fundamental upgrade that significantly improves the consistency and quality of your prints, reducing the common issues associated with the stock plastic extruder. By providing a more robust and reliable mechanism, you will get the most out of your prints.

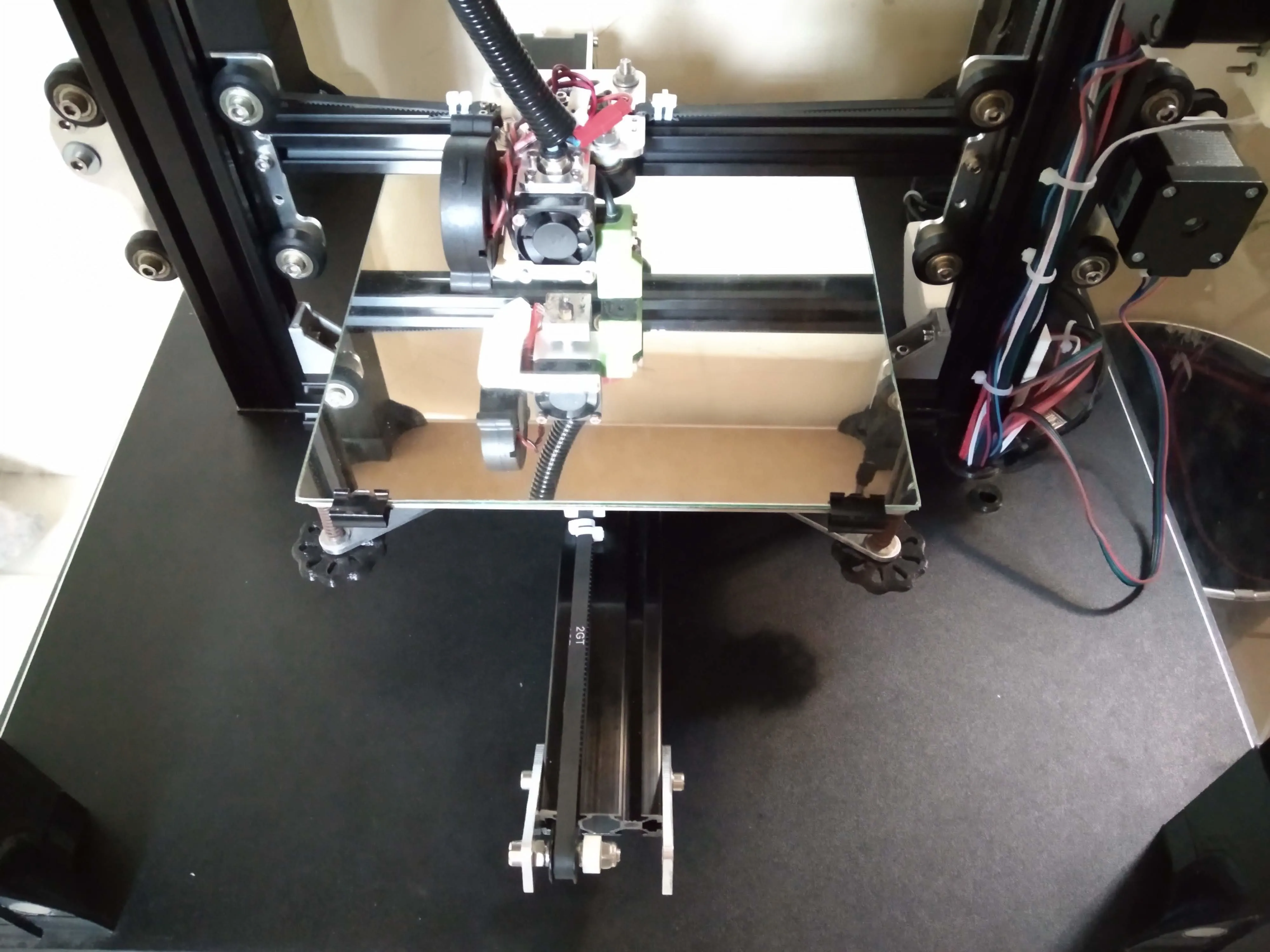

Aluminum Bed Leveling Kit

An aluminum bed leveling kit enhances stability and precision during the critical first layer of printing. This upgrade often includes a more robust leveling mechanism and a more rigid bed support system, reducing vibrations and ensuring the print bed remains level throughout the printing process. With an aluminum leveling kit, you can expect improved first-layer adhesion and fewer leveling adjustments during printing. This improvement is especially beneficial for larger prints, where bed stability is critical. The ability to maintain a perfectly level bed is the key to successful printing and reduces warping.

Aluminum Z-Axis Stabilizer

The Z-axis stabilizer made from aluminum significantly reduces wobble and improves the vertical stability of the print head. By providing a more rigid structure, it minimizes vibrations that can lead to layer shifting and print imperfections. This upgrade results in straighter, more accurate prints, particularly in the Z-axis. The installation of an aluminum Z-axis stabilizer makes a noticeable difference in print quality, especially for taller objects where stability is paramount. This leads to less noise and a better user experience when printing with this component.

Aluminum Frame Reinforcements

Upgrading the frame of your Tevo Tarantula with aluminum reinforcements provides a much more stable and rigid structure. This minimizes flex and vibration during printing, which directly translates into improved print quality. Aluminum frame reinforcements enhance the structural integrity of the printer, allowing for higher printing speeds and reducing the likelihood of print failures due to movement. A more stable frame is essential for achieving consistent and accurate prints, especially when working with larger projects or demanding materials. It also improves the durability and lifespan of the entire 3D printer. This gives the printer additional stability to print more consistently.

Aluminum Hotend

Replacing the stock hotend with an aluminum version offers significant advantages in terms of thermal management and print quality. An aluminum hotend provides more efficient heat distribution, which helps to maintain a consistent temperature and reduce the chances of nozzle clogs. This improvement is particularly useful when printing with materials that require precise temperature control, such as ABS or PETG. The improved thermal performance translates to smoother extrusion, better layer adhesion, and enhanced print detail. Additionally, aluminum hotends are typically more durable and resistant to wear, ensuring a longer lifespan and reliable performance. This contributes to better prints.

Installation and Setup

Installing aluminum parts on your Tevo Tarantula is usually straightforward. However, it’s important to approach the process systematically and with care. Familiarize yourself with the new parts, read the instructions provided by the manufacturer, and ensure you have the necessary tools. Careful installation prevents damage to the parts and ensures optimal performance. This section covers the essential aspects of installing aluminum upgrades, helping you to enhance your 3D printing experience. Properly installing these components is important to take advantage of their features.

Tools Needed

Before you begin, gather the essential tools for the installation. These typically include Allen wrenches (hex keys) of various sizes, a screwdriver set, pliers, and possibly a set of calipers for precise measurements. A small parts tray can be helpful to keep screws and small components organized. Always have the printer’s manual handy, as it contains specific instructions for disassembly and reassembly. Some upgrades may require additional tools or equipment, so check the manufacturer’s instructions for each specific part.

Step-by-Step Guide

Each aluminum upgrade will have its own installation process, but here’s a general guideline. First, power off and disconnect the printer. Then, carefully disassemble the existing component, noting the orientation and placement of each part. Install the aluminum replacement, ensuring all screws are tightened securely but not over-tightened. Refer to the manufacturer’s instructions for specific torque values. After installation, perform any necessary calibration adjustments. Finally, test the printer with a test print to verify the upgrade. This step-by-step process ensures a smooth and successful upgrade of your Tevo Tarantula.

Troubleshooting Common Issues

During or after installation, you may encounter minor issues. Common problems include incorrect alignment, loose screws, or calibration errors. If a component doesn’t fit, double-check the instructions and ensure you have the correct part. For loose screws, use the appropriate Allen wrench to tighten them. If your prints are still not coming out as expected, recalibrate the printer’s bed leveling, and adjust the Z-offset. If you’re facing issues with the hotend, verify your temperature settings are accurate for the type of filament you’re using. Addressing these common issues proactively can help you ensure smooth printing and prevent frustrating setbacks.

Where to Buy Aluminum Parts

Finding high-quality aluminum parts for your Tevo Tarantula is essential for maximizing the benefits of your upgrades. Several reliable sources offer a wide range of components. Consider the factors of pricing, quality, and customer support before making your purchases. Selecting the right vendor ensures your parts meet your expectations and are compatible with your printer. The following sections provide guidance on the most reliable and trustworthy sources to source your upgrades.

Online Retailers

Online retailers, such as Amazon, eBay, and specialized 3D printing stores, offer a vast selection of aluminum parts for the Tevo Tarantula. These platforms provide convenience, allowing you to compare prices, read reviews, and access a wide variety of options. When purchasing from online retailers, check the seller’s reputation, reviews, and return policies. Pay attention to product specifications and ensure that the parts are compatible with your printer model. Some specialized 3D printing stores provide tailored upgrades.

Local 3D Printing Shops

Local 3D printing shops offer a more personalized shopping experience, providing expert advice and hands-on support. These stores often stock a range of aluminum parts and can assist with selecting the right components for your specific needs. Visiting a local shop allows you to inspect the parts before purchase and ask questions directly. Local shops may also offer installation services or provide guidance on printer setup. Supporting local businesses and getting direct, expert support makes this a great choice.

Tips for Choosing Quality Aluminum Parts

Selecting the right aluminum parts is crucial for a successful upgrade. Here are some tips to help you choose quality components. Consider the material grade of the aluminum; higher grades typically offer greater strength and durability. Check the product reviews to gauge the quality and reliability of the parts. Ensure that the parts are compatible with your Tevo Tarantula model. Verify the dimensions of the parts and compare them with the original components. If possible, choose parts from reputable brands known for producing high-quality 3D printing accessories. By following these tips, you can confidently choose aluminum parts that will improve the performance and longevity of your printer. Quality is a priority when making any upgrade.

Conclusion

Upgrading your Tevo Tarantula with aluminum parts is a significant investment that yields tangible improvements in performance, durability, and print quality. From enhancing stability with aluminum frame reinforcements to boosting extrusion precision with an aluminum extruder, these upgrades address the limitations of stock components. By carefully selecting and installing these parts, you can transform your Tevo Tarantula into a more capable and reliable 3D printer. Remember to follow the installation steps carefully and to choose quality parts from reputable vendors. The result will be a 3D printer that consistently produces superior prints and provides a more enjoyable and efficient user experience. Investing in these upgrades will make a significant difference.