Machining Tarantula Mark II Top 7 Features

The Machining Tarantula Mark II is a state-of-the-art CNC machine, engineered for precision and efficiency. This blog post will delve into the top 7 features that make the Machining Tarantula Mark II a standout choice for manufacturers and engineers seeking to elevate their machining capabilities. From its advanced control systems to its robust construction and safety features, we’ll explore what sets this machine apart. Whether you’re a seasoned professional or new to CNC machining, understanding these features will help you determine if the Machining Tarantula Mark II aligns with your production needs.

Precision and Accuracy

At the core of the Machining Tarantula Mark II’s design is a commitment to precision and accuracy. This machine is built to deliver incredibly tight tolerances, ensuring that every part meets the exact specifications required. This level of accuracy is achieved through a combination of advanced technologies and meticulous engineering. High-quality linear guides and ball screws minimize friction and backlash, allowing for smooth and precise movements of the cutting tools. The machine’s rigid frame further enhances stability, reducing vibrations that could compromise accuracy. The result is a machine capable of producing complex geometries with exceptional fidelity, making it ideal for applications where precision is paramount. The use of closed-loop feedback systems constantly monitors and adjusts the cutting process, guaranteeing that the final product aligns perfectly with the design.

Advanced Control System

The Machining Tarantula Mark II is equipped with an advanced control system that significantly boosts its operational efficiency and ease of use. This sophisticated system allows for seamless programming and operation. It supports a wide range of G-codes, making it compatible with various CAD/CAM software solutions. The advanced control system ensures that even the most complex designs can be executed precisely. Sophisticated algorithms manage toolpaths, optimizing cutting strategies for speed and material removal rates. This results in faster production times without compromising on the quality of the finished product. The user interface is designed to be intuitive, providing operators with real-time information about the machining process, including tool position, spindle speed, and feed rates. The advanced control system also incorporates features such as tool wear compensation and automatic tool changes, which further automate the machining process, minimizing downtime and maximizing productivity.

User-Friendly Interface

The Machining Tarantula Mark II features a user-friendly interface designed to simplify the machining process, regardless of the operator’s experience level. The interface is intuitive, with a clear display that presents all the necessary information in an easily understandable format. The touch-screen controls facilitate quick adjustments and offer easy access to machine settings. Programming is simplified with the machine’s ability to import CAD/CAM files directly, minimizing the need for complex manual programming. The interface also provides real-time monitoring of the machining process, displaying tool paths, machine status, and potential errors. This real-time feedback allows operators to quickly identify and address any issues. The interface is designed to minimize the learning curve, allowing operators to quickly become proficient in operating the Machining Tarantula Mark II.

High-Speed Machining Capabilities

The Machining Tarantula Mark II is built for high-speed machining, allowing for rapid material removal and significantly reducing production times. This capability is a result of its powerful spindle motors, high-speed feed rates, and advanced control algorithms. High-speed machining reduces the time it takes to complete a project, allowing for faster turnaround times. The design of the machine minimizes vibrations, enabling it to maintain precision at high speeds. This makes it ideal for projects that require quick production without sacrificing the quality of the end product. This technology allows users to achieve finer surface finishes and tighter tolerances, leading to better end products and less post-processing. High-speed machining also allows for increased productivity and profitability.

Spindle Speed and Torque

The Machining Tarantula Mark II boasts a powerful spindle, providing the necessary speed and torque for a variety of machining tasks. The spindle’s high speed enables it to handle a wide range of materials, from soft plastics to tough metals. The torque ensures that the machine can maintain cutting power, even when working with difficult-to-machine materials. The spindle’s speed is precisely controlled, allowing operators to optimize the cutting process for different materials and applications. The combination of high speed and ample torque makes the Machining Tarantula Mark II a versatile machine capable of handling diverse manufacturing needs. The spindle’s performance is critical for achieving both efficient material removal and the desired surface finish, contributing to the overall quality and speed of the machining process.

Rapid Traverse Rates

Rapid traverse rates are a key feature of the Machining Tarantula Mark II, contributing to its overall efficiency. These rates refer to the speed at which the machine’s cutting tool can move between cutting positions without engaging in the machining process. High rapid traverse rates minimize non-cutting time, reducing the overall production time. The machine’s ability to quickly move the cutting tool allows for faster cycle times, boosting productivity. This is especially beneficial when machining parts with multiple features or when changing between different cutting operations. The speed and efficiency offered by these rapid traverse rates are essential for manufacturers looking to optimize their production processes and improve their overall throughput. The faster the tool can move between cuts, the more parts can be produced in a given amount of time.

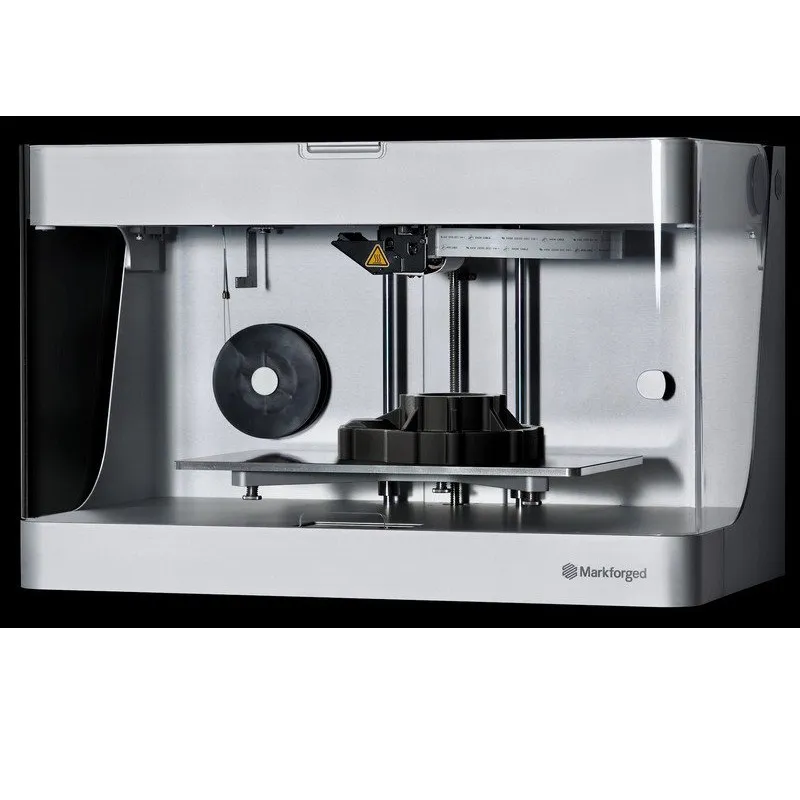

Robust Construction and Durability

The Machining Tarantula Mark II is built with a robust and durable construction, designed to withstand the rigors of continuous use in a manufacturing environment. The machine’s frame is constructed from high-quality materials, providing stability and minimizing vibrations. This rugged construction extends the machine’s lifespan, ensuring that it can perform reliably for many years. The components are selected for their durability and resistance to wear and tear. The machine’s design also incorporates features that protect it from damage, such as splash guards and coolant systems. These ensure that the internal components remain protected from debris and contamination. The robust construction translates to lower maintenance costs and reduced downtime. The Machining Tarantula Mark II is a reliable investment for manufacturers looking for a long-lasting and dependable machining solution.

Material Compatibility

The Machining Tarantula Mark II is designed to be compatible with a wide range of materials, increasing its versatility. This includes both metals and non-metals, allowing it to be used for a variety of applications. The machine can handle materials such as aluminum, steel, and various alloys. It can also machine plastics, composites, and other non-ferrous materials. This broad compatibility opens the door for manufacturers to take on a wider variety of projects. The spindle speed and torque can be adjusted to suit the material being machined. The machine’s ability to handle different materials makes it a valuable asset for any manufacturing operation, providing the flexibility needed to meet diverse customer demands. This material compatibility allows for various manufacturing processes and capabilities.

Work Envelope and Capacity

The Machining Tarantula Mark II boasts a substantial work envelope and capacity, allowing it to handle a wide range of part sizes and geometries. The machine’s work envelope defines the maximum size of the part that can be machined. Its design provides ample space for larger parts and complex shapes. This increased capacity allows for higher levels of productivity and the ability to meet diverse machining requirements. The machine’s table can support considerable weight, allowing for machining of heavier parts. The combination of a large work envelope and high weight capacity ensures that the Machining Tarantula Mark II can meet the demands of many manufacturing operations. This work envelope and capacity contribute significantly to the machine’s flexibility and ability to handle a variety of projects.

Automation and Integration Options

The Machining Tarantula Mark II offers a variety of automation and integration options. This allows manufacturers to streamline their processes and increase efficiency. The machine can be integrated with robotic systems, enabling automated loading and unloading of parts, reducing manual labor and increasing throughput. The machine is also designed to integrate with other manufacturing equipment, such as automated part feeders and inspection systems, allowing for a completely automated manufacturing cell. Software integration capabilities allow for seamless data transfer, providing real-time monitoring and control. The automation options increase efficiency and minimize human error, leading to higher quality parts and reduced production costs. These features help manufacturers optimize their production processes, improve productivity, and reduce operational costs.

Connectivity Features

The Machining Tarantula Mark II includes advanced connectivity features that enhance its functionality and integration capabilities. The machine can be connected to a network, allowing for remote monitoring and control. This enables operators to oversee the machining process from a distance, making adjustments as needed. The machine supports various communication protocols, such as Ethernet and Wi-Fi, facilitating data transfer and remote access. The connectivity features improve machine control and data management. Data can be easily transferred to and from the machine, enabling quick updates and modifications to part programs. These capabilities make the Machining Tarantula Mark II a highly adaptable and efficient machining solution for modern manufacturing environments. The ability to remotely monitor and control the machine provides greater flexibility and control over operations.

Software Compatibility

The Machining Tarantula Mark II offers broad software compatibility, ensuring seamless integration with existing CAD/CAM systems. The machine supports a range of file formats, simplifying the process of importing designs and toolpaths. The software compatibility streamlines the programming workflow, reducing setup time and increasing efficiency. The machine is compatible with popular software programs. This broad compatibility ensures that manufacturers can easily integrate the Machining Tarantula Mark II into their existing workflows. The machine’s software flexibility allows it to adapt to a range of software applications, making it a valuable addition to any manufacturing environment.

Safety Features

The Machining Tarantula Mark II incorporates several safety features designed to protect operators and ensure a safe working environment. These features are essential for preventing accidents and minimizing risks. The machine’s design prioritizes operator safety, reducing the chances of injury. These safety measures provide a secure and productive environment. The Machining Tarantula Mark II is designed to comply with industry safety standards. The safety features are critical to protecting operators and ensuring continuous safe operations.

Emergency Stops

The Machining Tarantula Mark II includes readily accessible emergency stop buttons. These buttons are strategically placed to allow immediate shutdown of the machine in case of any emergency. They provide a critical safety mechanism. The immediate shut-down prevents potential accidents and minimizes the risk of damage. The emergency stop system is a crucial safety feature, designed to protect operators. The presence and accessibility of emergency stop buttons is essential. The quick access to emergency stops guarantees that the machine can be immediately stopped.

Enclosed Design

The Machining Tarantula Mark II features a fully enclosed design, which helps to contain the machining process and protect operators from hazards. The enclosure prevents flying debris. This design also helps to reduce noise levels. The enclosure protects the machine from external contaminants. The enclosed design contributes significantly to workplace safety. This enclosed design makes the Machining Tarantula Mark II a safe choice for any manufacturing environment.

In conclusion, the Machining Tarantula Mark II stands out as a top-tier CNC machine due to its exceptional combination of precision, speed, durability, and advanced features. Its user-friendly interface and robust construction make it an ideal choice for manufacturers seeking to enhance their machining capabilities. With its high-speed machining capabilities, automation options, and focus on safety, the Machining Tarantula Mark II is an investment in efficiency and quality. Whether you’re producing complex parts or seeking to streamline your production, the Machining Tarantula Mark II is a reliable and versatile solution that can elevate your manufacturing process to the next level.