What is a Direct Drive Extruder

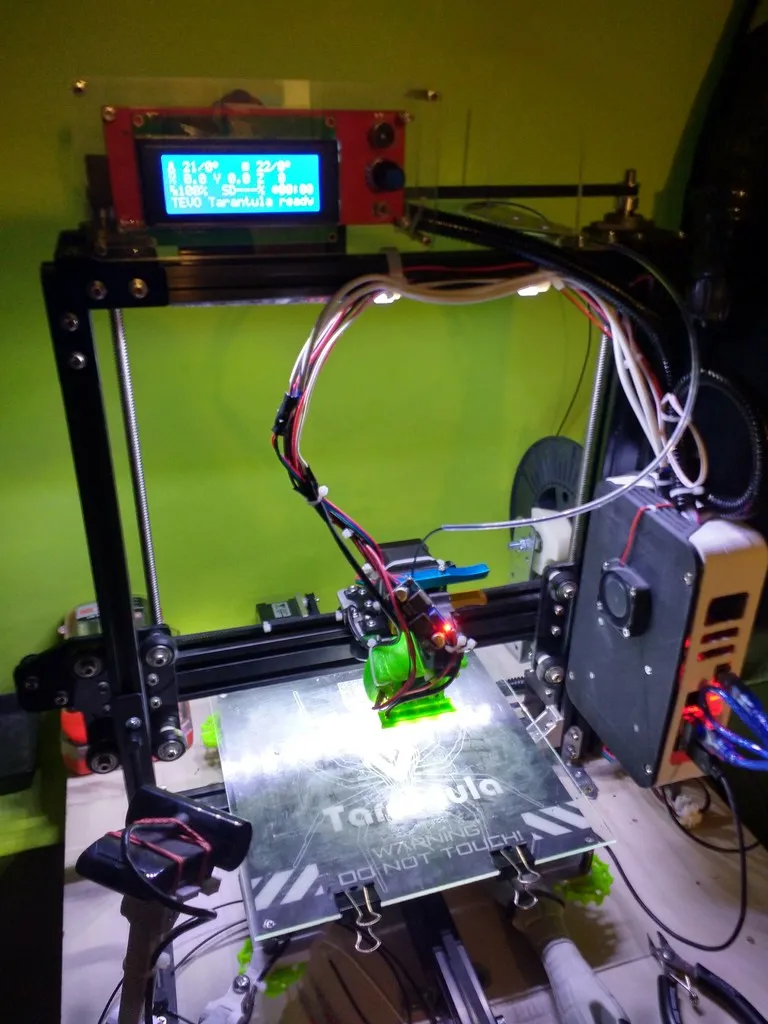

A direct drive extruder is a 3D printer component that feeds filament directly into the hot end. Unlike bowden tube setups, where the extruder motor is mounted on the printer frame and pushes the filament through a long tube, a direct drive extruder mounts the extruder motor directly above the hot end. This close proximity offers several advantages, primarily in filament control and print quality. It’s a popular upgrade for many 3D printers, and particularly beneficial for machines like the Tevo Tarantula, which can see significant improvements from the upgrade. The direct drive setup minimizes the distance the filament must travel, allowing for more precise control over extrusion and retraction. This is a critical factor in achieving high-quality 3D prints, especially with flexible filaments.

Benefits of a Direct Drive Extruder

Upgrading to a direct drive extruder offers numerous benefits for your 3D printing experience, most notably a boost in print quality and the ability to print a wider range of materials. By mounting the extruder motor directly above the hot end, filament is fed more precisely, reducing issues common in bowden setups. This results in sharper details, cleaner prints, and a generally improved overall aesthetic. Moreover, direct drive setups allow for more effective retraction, which is critical for reducing stringing and oozing, problems that often plague 3D prints. Furthermore, the direct drive configuration is particularly advantageous when using flexible filaments, which can be difficult to feed reliably through a bowden tube. The direct drive setup eliminates much of the friction and resistance, leading to smooth and consistent extrusion.

Improved Filament Control

One of the most significant benefits is the enhanced filament control. The shorter distance the filament travels between the extruder and the hot end drastically reduces the lag and delay inherent in bowden tube systems. This direct connection allows for much quicker response times, enabling the printer to start and stop the flow of filament more accurately. This is particularly helpful when printing intricate designs with fine details, overhangs, and bridges, where precise control over filament deposition is crucial. The immediate responsiveness of a direct drive setup minimizes the chances of under-extrusion or over-extrusion, thereby ensuring consistent and reliable prints. Consequently, prints tend to be more dimensionally accurate and have a cleaner overall appearance, with reduced instances of defects and artifacts.

Reduced Stringing and Oozing

Direct drive extruders excel at minimizing stringing and oozing, common issues in 3D printing where small strands of plastic appear between printed parts. This improvement stems from the ability to perform more effective and responsive retractions. Retraction is the process of pulling the filament back from the nozzle when the printer moves between different parts of a print. With a direct drive setup, the retraction distance can be shorter and more precise because the extruder is right above the hot end. This results in less filament leakage and a cleaner print. This reduction in stringing drastically improves the surface finish of your prints and reduces the need for post-processing, making your 3D printing process much more efficient and producing much better results. Properly tuned retraction settings can virtually eliminate stringing.

Enhanced Print Quality

Ultimately, the advantages of a direct drive extruder contribute to enhanced print quality. The improved filament control, reduced stringing, and more responsive extrusion all combine to create prints with finer details, sharper corners, and a more refined surface finish. This is particularly noticeable in complex prints with intricate geometries, where the precision offered by a direct drive setup shines. This increased print quality translates to more professional-looking models and a greater level of satisfaction with your prints. The ability to print with a wider range of materials, including flexible filaments, also expands your creative possibilities, allowing you to explore new projects and designs.

Weight Considerations and Potential Drawbacks

While direct drive extruders offer many benefits, there are a few considerations to be aware of before making the switch, particularly regarding weight. The added weight of the extruder motor and associated components mounted directly on the print head can introduce inertia, potentially affecting print speeds and causing vibrations, especially at higher speeds. It’s crucial to ensure your printer’s frame is sturdy enough to handle the increased weight. This might mean adjusting print settings to compensate for the weight, or in some cases, upgrading other components of your printer to maintain the same print quality or print speed. The trade-off between print quality and speed is an important aspect to consider when deciding whether a direct drive setup is the right choice for your Tevo Tarantula.

Increased Nozzle Weight

The direct drive setup increases the overall weight of the print head because the extruder motor is mounted directly above the hot end. This added weight can potentially lead to a few issues. Firstly, it puts more strain on the X-axis, potentially causing vibrations during printing, which can impact print quality. Secondly, the printer may require recalibration of its acceleration and jerk settings to optimize performance and reduce these vibrations. Lastly, the increased weight can affect the printer’s ability to quickly change directions, especially on fast movements. Therefore, it’s essential to make appropriate adjustments in the slicer settings to mitigate these issues. Careful calibration and adjustment can ensure that the direct drive system does not compromise the print quality and speed.

Slower Print Speeds

The added weight of a direct drive extruder can, in some cases, necessitate a reduction in print speed. The increased inertia of the print head, due to the motor’s presence, makes it harder for the printer to rapidly change direction. This is particularly noticeable in prints that involve frequent, rapid movements. However, the degree to which print speed is affected varies depending on the printer’s design and the quality of the components. Some users find that they can maintain similar speeds with a direct drive setup by optimizing their printer’s settings and using lighter-weight components. Other users may need to slightly reduce their print speeds to achieve optimal print quality. It is important to experiment with different settings to find the optimal balance between speed and quality for your specific setup. Fine-tuning the acceleration and jerk settings can help minimize any negative effects on print speed.

Installation and Compatibility

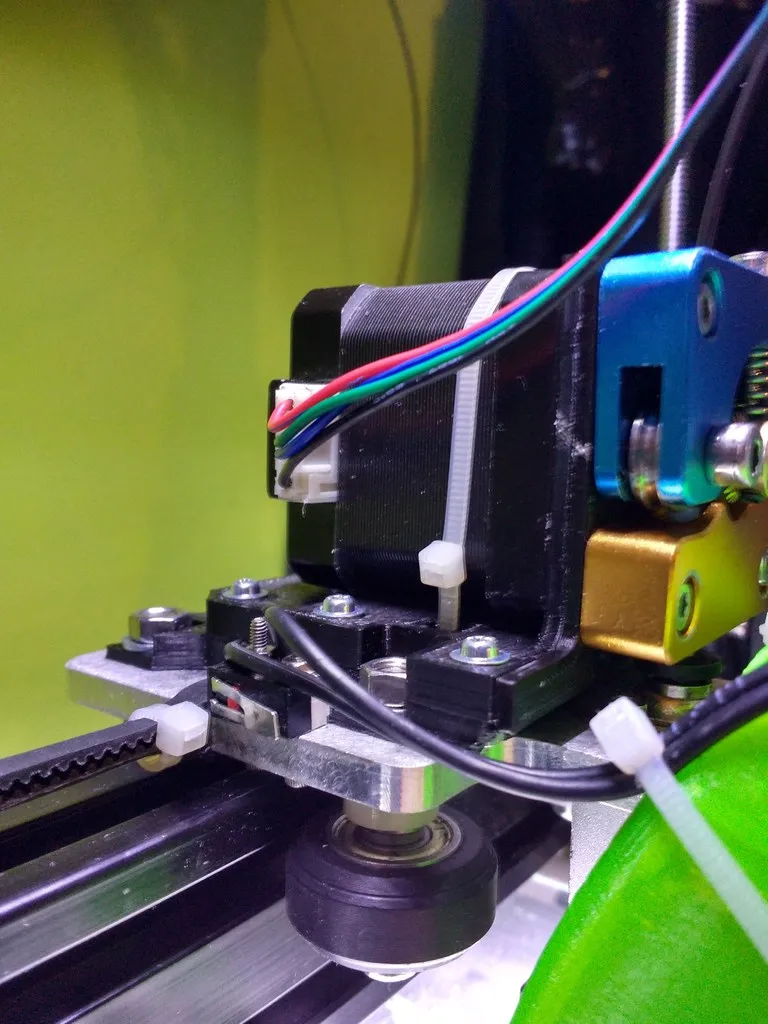

Installing a direct drive extruder on your Tevo Tarantula can significantly improve its performance. However, the process requires careful planning and execution. It is important to understand the components involved, the compatibility of the parts, and the steps required for a successful installation. Before starting the upgrade, make sure you have the necessary tools and hardware. Detailed instructions and guides are readily available online. The upgrade involves replacing the existing extruder setup with a direct drive system. This typically includes mounting the extruder motor directly above the hot end and connecting the wiring to the control board. Proper calibration and adjustments are crucial after installation to ensure optimal printing results.

Compatibility with Tevo Tarantula

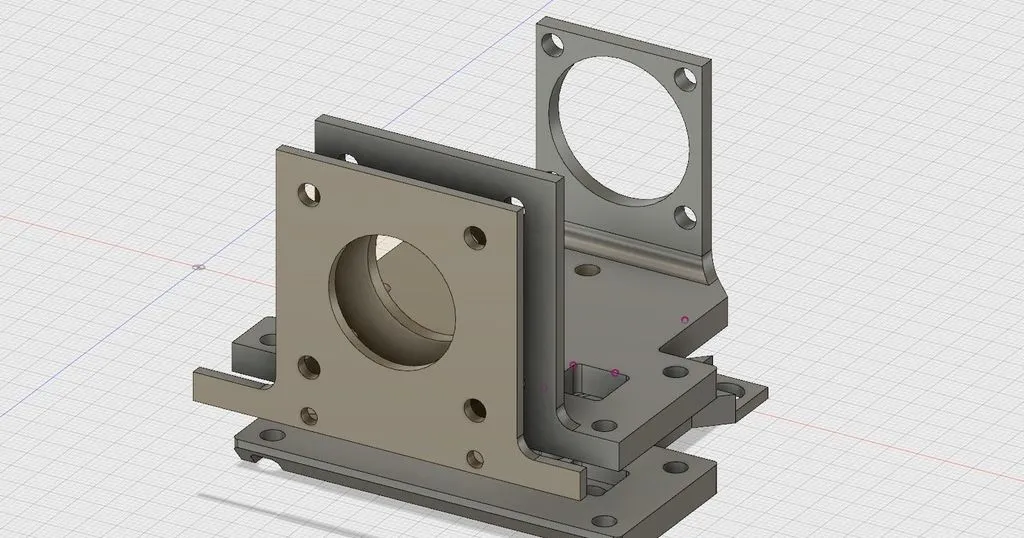

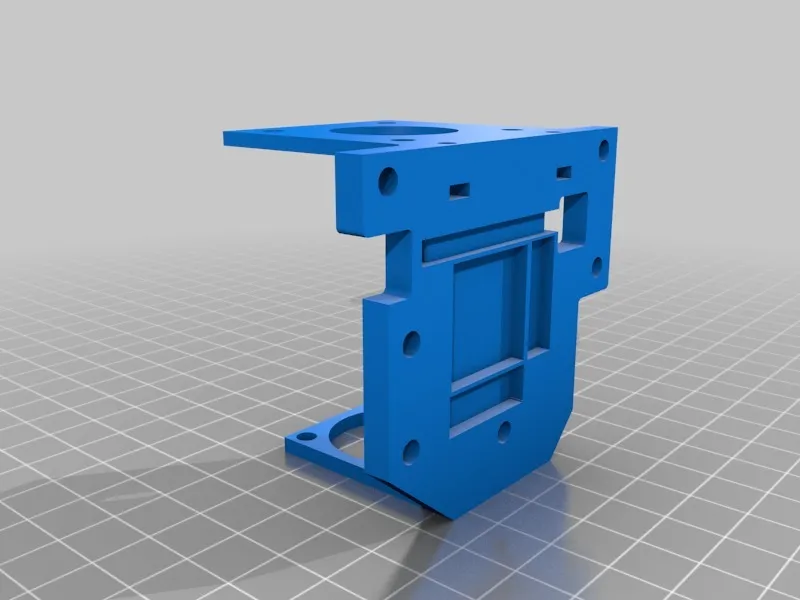

The Tevo Tarantula is a popular 3D printer known for its affordability and versatility. When choosing a direct drive extruder for your Tevo Tarantula, compatibility is a crucial factor to consider. Some direct drive kits are designed specifically for the Tevo Tarantula, offering a straightforward installation process and optimized performance. Look for kits that include mounting brackets and any necessary adapters specifically designed for your printer model. This ensures a proper fit and simplifies the installation process. Check the specifications of the direct drive kit and compare them to your printer’s original setup. If you are using a different hot end, you also need to ensure its compatibility with the chosen direct drive kit. Consulting online resources, forums, and reviews from other Tevo Tarantula users is highly recommended to find the most suitable and compatible direct drive option.

Required Hardware and Tools

Before you begin the direct drive upgrade, it’s important to gather all the required hardware and tools. The exact components will vary depending on the specific direct drive kit you choose, but essential items typically include the direct drive extruder itself, mounting brackets, screws, and possibly a new hot end and/or cooling fan. Also, you’ll likely need a set of Allen wrenches or hex keys, a screwdriver, and possibly a multimeter for troubleshooting. Always read the installation instructions that come with your direct drive kit thoroughly. Some kits may require you to modify existing parts on your Tevo Tarantula, such as drilling new holes or adjusting wiring connections. Having all the necessary tools and understanding the installation process beforehand will make the upgrade smoother and less frustrating. Ensure you have the tools and expertise to handle the electrical and mechanical aspects of the installation. Refer to online tutorials or consult experienced users if you are uncertain about any step.

Top 5 Must-Know Facts about Direct Drive Extruders

- Direct drive extruders mount the motor directly above the hot end for improved filament control.

- They significantly reduce stringing and oozing due to enhanced retraction capabilities.

- Print quality is enhanced, providing sharper details and cleaner surfaces.

- Increased nozzle weight and slower print speeds are potential drawbacks that require calibration and adjustments.

- Compatibility and proper installation are crucial for optimizing performance with the Tevo Tarantula.